- home

- Dried Seafood

- Product Description of Dried Scallops

Dried Scallops

The 4-year old scallops that had been cultivated in the open sea for four years using the seabed ranching method becomes the raw material for dried scallops.

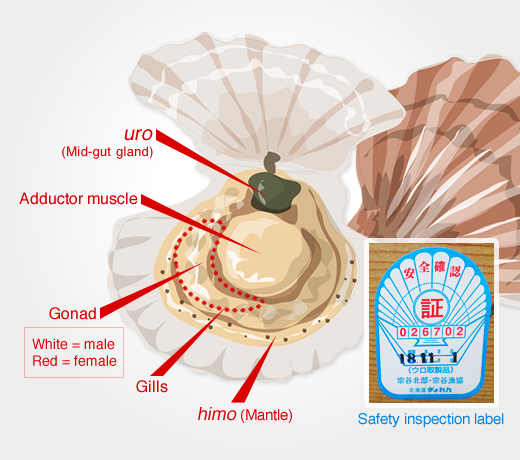

The scallop has a particularly large ligament (adductor muscle) among bivalves. This muscle is removed and processed into products - dried scallop (shiroboshi) or frozen scallop (tamarei).

The mantle is known as himo and has concentrated umami flavor just like the adductor muscle. It is processed into snacks and delicacies.

The mid-gut gland is known as uro and could be poisonous and is therefore not for consumption. All scallop products including dried scallop handled by the Hokkaido Federation of Fisheries Cooperative Associations has been certified with a label (safety inspection label) that guarantees that the uro has been properly removed.

World’s Top-Quality Dried Scallops Come from Japan

Adductor muscles of live scallops caught off the Sea of Okhotsk coast along Hokkaido are removed extremely fresh and immediately put to processing.

The process starts with meticulous control of the freshness of harvested scallops. The production processes have detailed requirements and processing control is applied with expert technology that finetunes the processes to adapt to weather and scallop conditions. The finished product is guaranteed in quality and safety by inspection and grading conducted by the Hokkaido Federation of Fisheries Cooperative Associations. All of these above are essential elements in ensuring that the dried scallops from Hokkaido is of the world’s topmost quality.

Dried scallops produced in China are mainly made from frozen scallops. They are not produced under a system comparable to that in Japan with its production, process control, and inspection/grading, therefore resulting in clear differences in quality. For example, the water content could be high, the scallops could be too salty due to large additions of salt to increase yield (weight), the scallops could contain contaminants such as sand, or the products could have a short shelf life.

As the dried scallops made in China are not as fully flavored, many more scallops are needed to produce the same taste in cooking. In some cases, using Chinese products could end up costing more than using dried scallops from Japan.

Best Before Date & Storage

As dried scallop is a dried preserved food, product deterioration is relatively slow. However, in order to preserve its original quality for as long as possible, it is important to store the product in conditions with no rapid big temperature changes. Ideally, dried scallops should be stored between 5°C and 15°C and humidity level at 60%. The shelf life of dried scallops made in Japan under proper production control is normally set at five years from manufacture. In some cases, however, there will be no problem with consuming the products after this date.

Examples of Deterioration (browning & powdering)

Browning: When the product loses its original golden color and turns brown

The main causes of brown discoloration lie in the processing. Some dried scallops become prone to browning due to conditions of boiling, oven drying, natural air drying, or moisture balancing. Some scallops are naturally prone to browning when dried. The browning mechanism is a chemical reaction called amino carbonyl reaction, in which glycogen contained in the scallop decomposes. Excessive browning as shown in the photograph leads to less umami or nutritional value such as loss of amino acids.

Powdering: When white powder erupts and adheres to the surface

Powdering may result from the surface deposition of salt or amino acid contained in the scallop or from microorganism activity such as that of mold.

*Dried scallops produced in China are said to be subject to relatively fast degradation of these kinds due to their moisture content and different processing control applied.

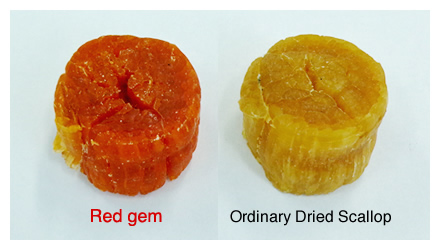

Red Dried Scallop (akadama)

Very occasionally, brightly colored reddish orange dried scallop is produced like the one shown in the photo on the left. This is not a defective product, but a valuable scallop called akadama (red gem). Only one or two in a thousand is said to be found.

The reason why the scallop develops a red color is pectenelone, the pigment that occurs widely naturally. Most likely, the scallop eats diatom (a species of plant plankton) that contains this pigment, then coloring the adductor muscle.

Pectenelone is a useful pigment with powerful antioxidative properties together with anticancer action, promising prevention of oxidation of the body and development of cancer. The akadama dried scallop and ordinary dried scallop are mostly no different in their content of crude protein, minerals, glycogen and free amino acids.

[Source: Fisheries Processing Data No. 36; Hokkaido Research Organization, Abashiri Fisheries Research Institute]

Difference in Dried Scallop Shapes

These two dried scallops in the picture are of the same size SA grade, 4.0 g in weight each. The one on the left is flat and looks bigger from the top but is not thick. The one on the right looks smaller from the top but is thicker.

*Dried scallops are graded in size by weight. Click here for more details of dried scallop grading.

Such differences in the shape of dried scallops are largely due to the difference in the habitat of the original scallop. With fast currents and rocky seabed or gravel ground, the scallop adapts its shell so as to cling on, making it thick and round and resulting in the adductor muscle getting taller. By contrast, if the current flows slowly and the seabed is sandy or muddy, the scallop is less prone to being washed away. The shell therefore gets flatter and the adductor muscle also becomes flat in shape.

The northern areas of the Sea of Okhotsk produce scallop with tall adductor muscles and the southern areas tend to produce flat ones.